Email: info@ktexim.com | Call: +91-8048954878

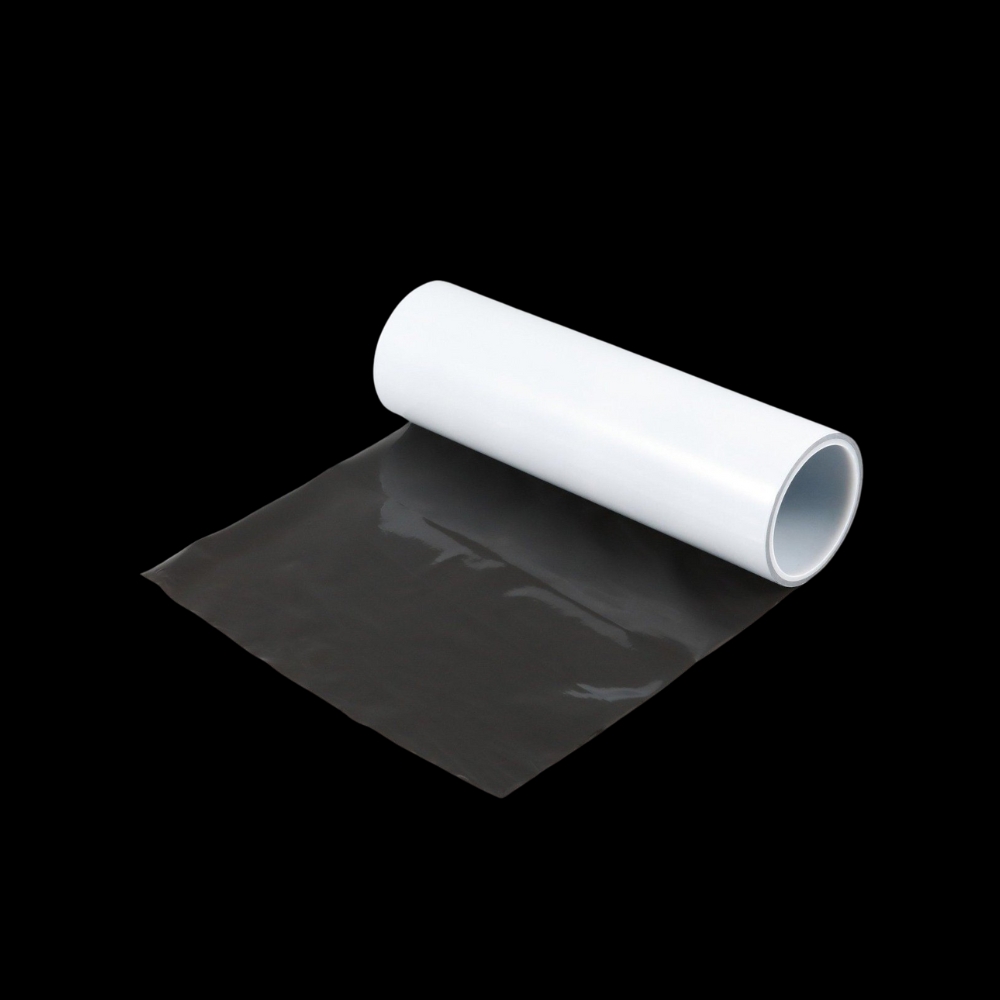

Black White Surface Protection Film

Product Overview

Industries :

- Aerospace

- Automotive

- Building & Construction

- Chemical

- Solar

- And More!

Have any Questions?

+91 8048954878

Black White Surface Protection Film

KTE Black White Surface Protection Film is a specialized protective film designed to safeguard surfaces, particularly those made of steel, uPVC (unplasticized polyvinyl chloride) windows, doors, utensils, and steel machinery, during various stages of production, transportation, installation, and use. Here’s a detailed overview of its uses and properties:

Uses Across Industries

- Steel Surfaces: The film is commonly used to protect steel surfaces, such as sheets, coils, panels, and finished products, from scratches, abrasions, and corrosion during manufacturing, processing, and transportation. It helps maintain the integrity and appearance of steel components throughout the production and supply chain.

- UPVC Windows and Doors: KTE Black White Surface Protection Film provides temporary protection for uPVC windows, doors, and profiles during fabrication, transit, and installation. It shields the surfaces from scratches, dirt, and damage caused by handling, ensuring that the final products reach customers in pristine condition.

- Utensils and Kitchenware: The film is employed to protect stainless steel utensils, cookware, and kitchen appliances from scratches, stains, and handling marks during storage, shipping, and retail display. It preserves the aesthetic appeal of the products and enhances customer satisfaction upon unboxing.

- Steel Machinery and Equipment: Industrial machinery, equipment, and components made of steel can benefit from the protective properties of the film. It prevents surface damage, corrosion, and contamination during storage, assembly, and installation, prolonging the lifespan and performance of the machinery.

Properties and Features

- Dual-Sided Color Design: KTE Black White Surface Protection Film features a dual-sided design with black and white layers. The black side is typically used to provide UV protection and heat resistance, while the white side offers scratch resistance and visibility for branding or labeling.

- High-Quality Adhesive: The film is equipped with a durable adhesive backing that ensures secure adhesion to surfaces without leaving behind residue or causing damage upon removal. The adhesive strength is optimized to provide reliable protection while allowing for easy application and clean removal.

- Weather Resistance: KTE Black White Surface Protection Film is engineered to withstand exposure to various environmental conditions, including moisture, sunlight, and temperature fluctuations. It remains stable and effective in protecting surfaces outdoors or in challenging environments.

- Customizable Sizes and Thicknesses**: The film is available in customizable sizes and thicknesses to accommodate different surface dimensions and protection requirements. Whether covering large steel panels or small utensils, businesses can tailor the film to fit their specific applications, minimizing waste and optimizing cost-effectiveness.

- Easy Identification: The dual-sided color design of the film enables easy identification of the protected surfaces. The contrasting black and white layers facilitate quick visual inspection, ensuring that the film is applied correctly and providing clear indication of when it needs to be removed.

- Cost-Effective Protection**: By providing a temporary barrier against damage and contamination, KTE Black White Surface Protection Film helps reduce the need for costly repairs, rework, or replacements of surfaces. It offers a cost-effective solution for preserving the quality and appearance of products throughout their lifecycle.

In summary, KTE Black White Surface Protection Film offers versatile and reliable protection for steel surfaces, uPVC windows and doors, utensils, and steel machinery across various industries. With its dual-sided color design, high-quality adhesive, weather resistance, and customizable features, this protective film ensures that surfaces remain pristine and protected during every stage of their journey from production to end use.